A few words

About us

our commitment to quality

Quality from start to finish

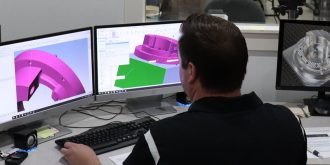

From design to production, our focus is always to provide a quality product at a competitive price. Serving medical, orthodontic, automotive, and aerospace industries, we understand how important leadtimes are. We have in house heat treat, grinding, machining, and EDM capabilities. We use Solidworks CAD and Esprit CAM products and work directly from customer provided models or can design your product or tooling at our facility. Using Mitsubishi EDM drill, Wire EDM, and Conventional “Ram type” or sinker EDM, we are able to supplement your shop on a time and material basis. We are always pleased to be involved at any level of your process that will help you achieve success. Premium Tooling and EDM services!

Microtech Precision, Inc.

Working for you

Microtech Precision, Inc. was started in 2006 to fill the need for a quality EDM job shop in the North West. Since then we have grown to a full service tool and mold shop. We design and build molds, tool and die, fixtures, gages, and Inspection tools. We also do EDM job shop work, using Mitsubishi EDM drill and 4 Wire EDMs, a EA12V advance sinker with C-axis and 20 position tool changer, and a new EA8 Sinker.

Our Services

- EDM- Wire, Sinker, EDM Drill

- Surface Grinding

- Machining- Turning and Milling

- Heat Treat

- Fabrication

- Automation

- Design- Solid Works

- Programming- Esprit

Our Future

We will continue to add the newest generation equipment and evolve to meet our customers needs as they arise. We are in process of adding procedures and documentation to meet our customers requirements of ISO 13485.

dedicated staff

About our team

John Ashton

Our Team